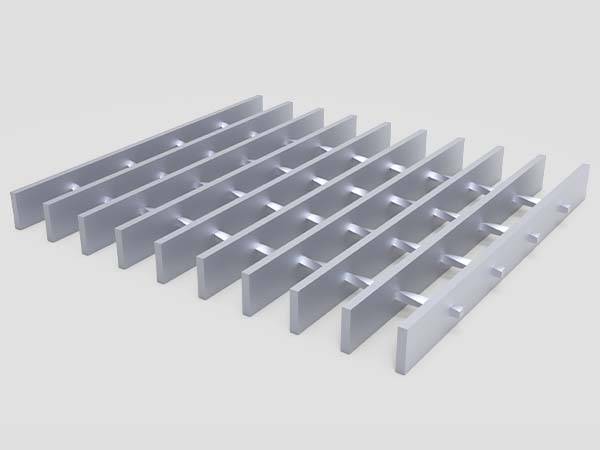

Plain surface

Aluminum grating is an ideal choice when corrosion-resistant, lightweight materials that do not affect its load capacity and mechanical strength is required. Made of ASTM B221, 6063 or 6061 alloy, aluminum grating has great versatile and durable and is mainly used for platform ceilings and outdoor curtain walls.

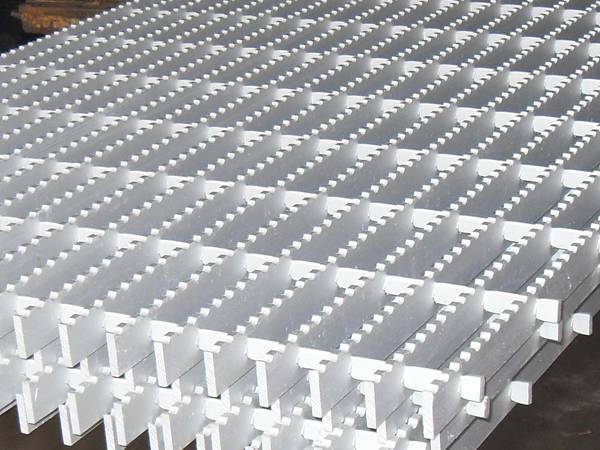

Aluminum grating

Aluminum grating details

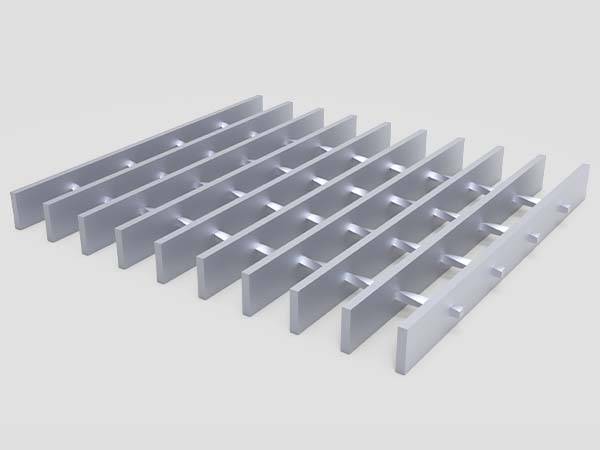

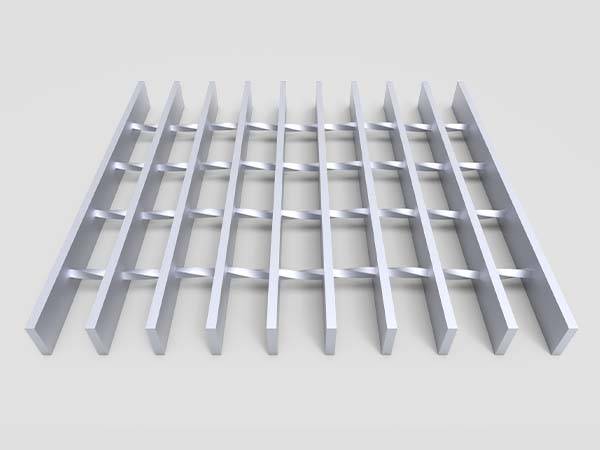

Plain surface

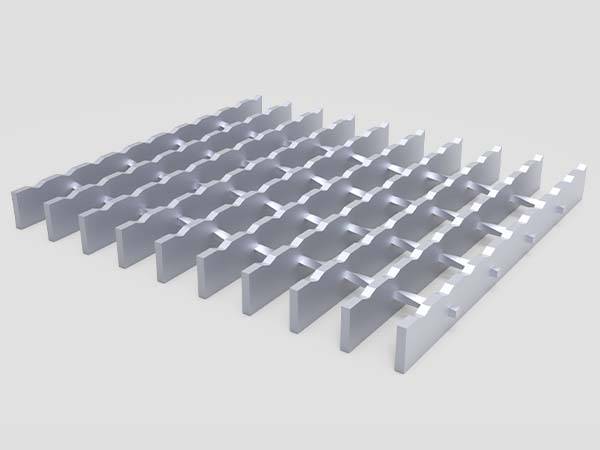

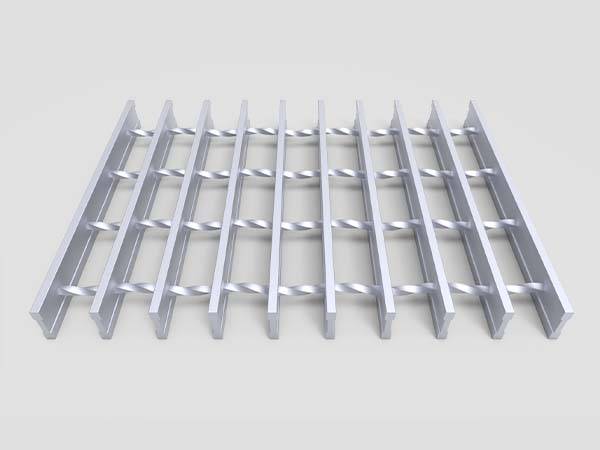

Serrated surface

Aluminum grating are generally available in four types: swaged rectangular aluminum grating, swaged I-bar aluminum grating, swaged flush-top aluminum grating, and dovetail pressure locked aluminum grating.

Dimensions

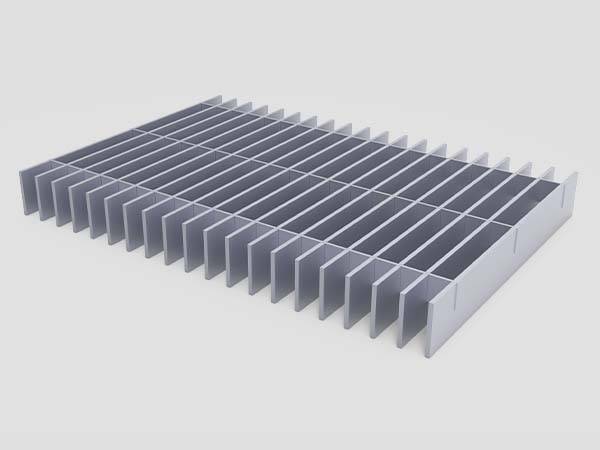

Cross bars are fully locked within the bearing bars, slightly below the top surface. It has clean and crisp lines. With nearly 80% open area, it is commonly used in public areas and is the industry accepted standard for industrial applications. If anti-slip is required, swaged rectangular aluminum gratings with a serrated surface are available upon request.

Specification

Swaged rectangular aluminum grating (horizontal)

Swaged rectangular aluminum grating (vertical)

Dimensions

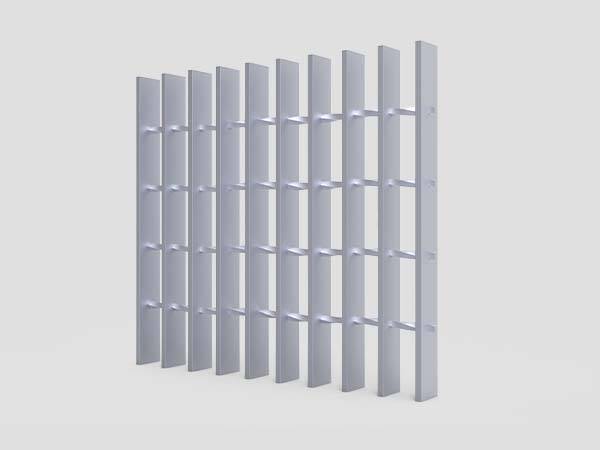

Supported by I-shaped extruded bearing bars, swaged I-bar aluminum grating carries the same load as the swaged rectangular aluminum grating with lighter weight and less costs. In addition, the striations at the top and bottom surfaces of the I bar increase the friction and provide high slip resistance performance.

Specification

Swaged I bar aluminum grating (horizontal))

Swaged I bar aluminum grating (vertical)

Dimensions

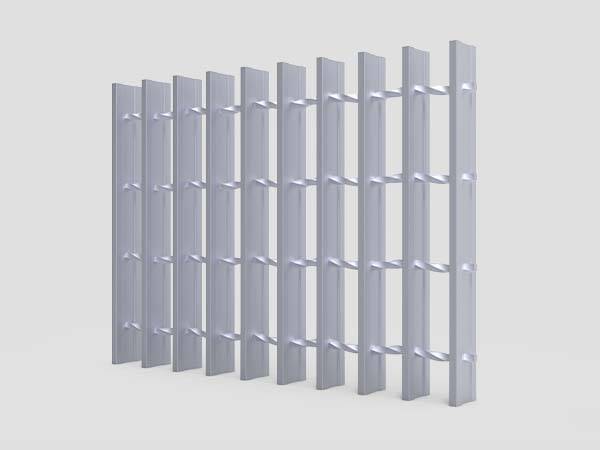

Cross bars are permanently locked within the bearing bars to lock the pressure via unique extruded cross bars. Swaged flush-top aluminum grating provides an enhanced walking surface for areas subject to continuous pedestrian traffic. If anti-slip is required, we can provide swaged flush-top aluminum gratings with a serrated surface. It is mainly used for public areas.

Specification

Swaged I bar aluminum grating (horizontal)

Swaged flush-top aluminum grating (vertical)

Dimensions

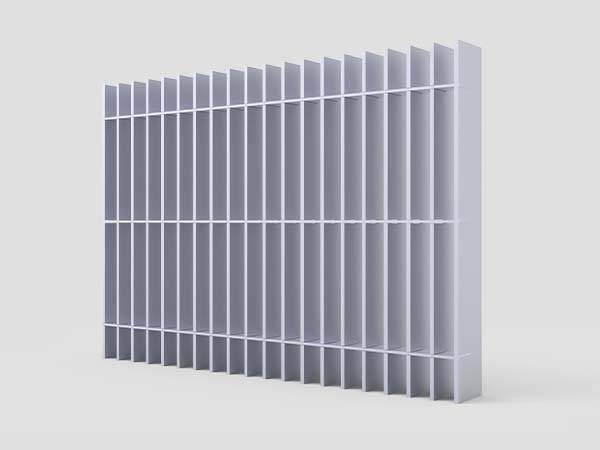

Dovetail pressure locked aluminum grating is manufactured by inserting deep rectangular cross bars into pre-punched bearing bars to form an interlocking structure with strong lateral stability. Its neat appearance and tight spacing make it popular in architectural designs and is commonly used as sun shades and infill panels.

Specification

Dovetail pressure locked aluminum grating (horizontal)

Dovetail pressure locked aluminum grating (vertical)

Application

Because of its light weight, corrosion resistance, and non-sparking, Aluminum gratings are widely used in indoor ceilings, outdoor curtain walls and other decorative applications due to its lightweight, excellent corrosion resistance and non-sparking properties. It is suitable for industrial applications where the strength-to-weight ratio is important, such as wastewater treatment plants. It is mainly used for safety protection and served as walkways, floors, platforms, stair treads, fences, etc.

Aluminum gratings for interior ceilings

Aluminum gratings for sun shades

Aluminum gratings for platform walkways

Aluminum gratings for building facades