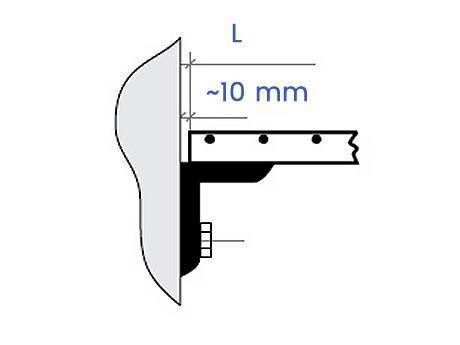

ML-01: The steel grating floor should be placed 10 mm away from the edge of the support.

ML-01: The steel grating floor should be placed 10 mm away from the edge of the support.

ML-02: The steel grating floor should be placed on 10 mm away from support edge.

ML-03: When you install steel grating floor close to walls or other metal elements, leave 10 mm interval of them.

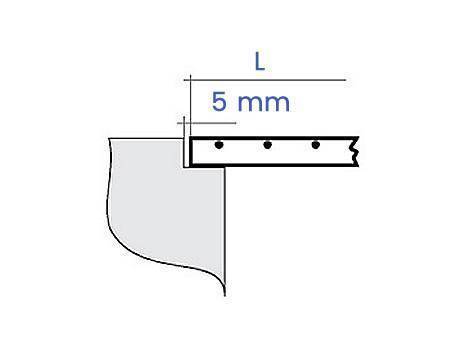

ML-04: Steel grating floor installed in a corner, the interval should be 5 mm on each side. If installed at the corner, the gap should be not less than the radius of curvature.

ML-05: Steel grating placed on the support panel, the edge of the steel grating is 15 mm away from the edge of support panel.

ML-06: Protruding element along the boundary of the grating layout. The distance between the protruding point and the grating floor is 10 mm.

ML-07: Steel grating floor and other things are all on the support at the same time, there should be 10 mm between them.

ML-08: If there is a barrier in the middle of steel grating floors, distance between steel grating and barrier at least is 30 mm.

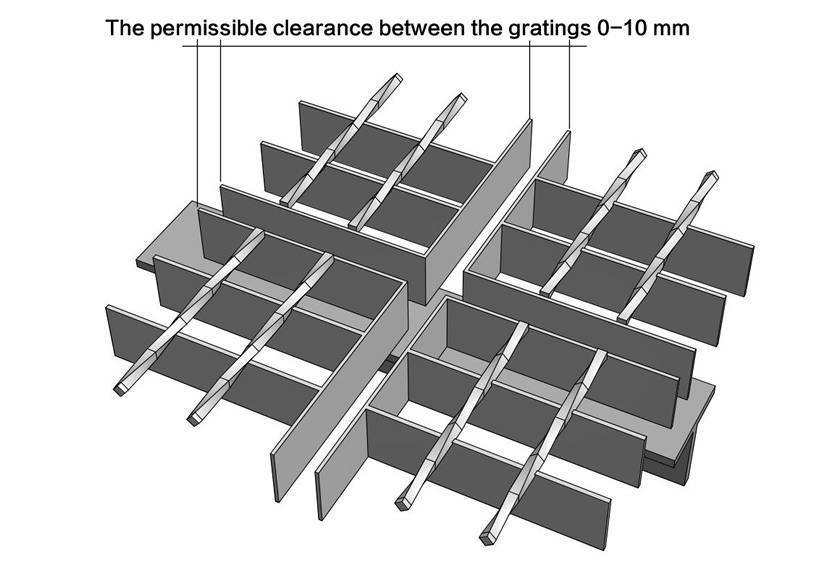

ML-09: The picture means permissible clearance between each steel grating should be 0-10 mm.

When you intend to lay the steel grating floor on supports, there should be permissible clearance among the each steel grating floor or between steel grating floor and other things.

In the period of designing where the steel grating should be place, we assumed that the distance between each steel grating is zero, but, bar gratings are manufactured with tolerance.

Observing the distances shown in the drawings above and ensure the proper position for laying steel grating on the supports.