EnZar®

Hot Dip Galvanized Steel Grating for Platform & Corridor Channel

The steel grating structure is light. It owns good carrying capacity. The steel grating is safe and non slip. It is easy to install and tear down. It does not need much material and it is durable. The steel grating owns aesthetics. The steel grating is ventilated and transparent. It's also easy to clean the steel grating. These steel bar gratings is widely used in the projects such as petro-chemical industry, firepower electric generation, water power industry, harbor and docks, pharmacy, auto manufacture, paper making, city planning and real estate. The steel grating can be used as platform, floor, corridor channel, stair tread, trestle, wall fence, trench cover, well cover, ceiling board and other facilities. We would use the steel grating for cement plant. We use the steel grating as the platform, corridor channel and stair tread.

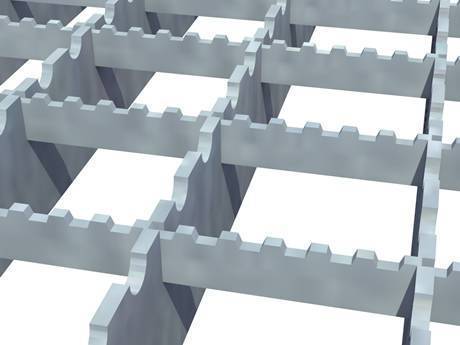

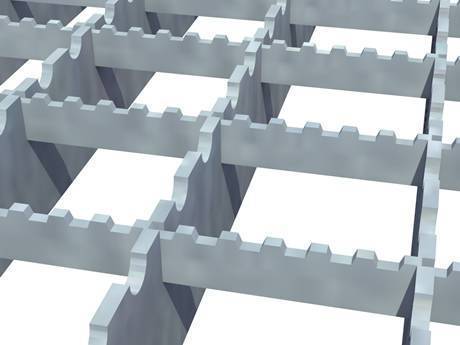

The steel grating with serrated type is more strong and anti-slipping.

The structure.

The steel grating could be used as the overhaul platform, such as humidity tower, dust collector, hoist and feeder equipment. It is also used for support corridor, belt conveyors, screw conveyors, chain conveyors, air transport chutes corridor and platform. Steel grating is used for cable bridge corridor, the connection among the building channel, the equipment inspection channel and stairs.

The design demands.

The loads.

The loads for the steel grating should meet the design needs of the safe loads needs. For the single walkway channel, the loads should be more than 3.0 KN /m2. For the double walkway channel , the loads for the steel grating should be more than 5.0 KN /m2. For the high density walkway board, the loads should be more than 7.5 KN /m2. For the steel grating on the traffic road, the loads would increase 25% when the wheel pressure increase 10%. If there are cutouts on the steel grating, the other parts should have the same loads.

The design demands for the platform passage.

- The deformation degree should not be more than the 1 /200 of the span when the steel grating platform are under loads. The deformation degree could not be more than 10 mm.

- The steel grating would not deform when the real loads is 1.5 times that of the design loads.

- The steel grating would not crack when the real loads is 3.0 times that of the design loads.

The design demands for the stairs tread.

- The deformation degree for the tread should not be more than the 1/200 of the span under the design loads. And the biggest deformation degree could not be more than 6 mm.

- The stairs tread would not deform when the real loads is 1.5 times that of the design loads.

- The stairs tread would not crack when the real loads is 3.0 times that of the design loads.

The steel grating design.

The spacing between the bearing bar steel is 30 mm, 35 mm or 40 mm. We should decrease the process times and the wastage, and design the steel grating as the following demands.

- The size of the steel grating is 6000 mm × 1000 mm. The distance among the boards should be 1000 mm. The gap between the boards should be 3–10 mm. We should use the last board to make the size complete.

- If the width of the board is less than 1000 mm, we should choose a close width of the steel grating from the manufacturer.

- The length of the steel grating can be optional, but it is best to be an integral multiple of 50 mm.

- The width of the stairs tread should be 700 mm, 800 mm or 900 mm.

The installation.

The installation demands.

- We should install the steel grating according to the steel structure. The steel grating would not move horizontally and would not be out of the support frame.

- The support length on the edge of the steel grating should be more than 25 mm.

- If we do not need move the steel grating, we should install the steel grating by welding and weld the steel grating on the frame.

- If we need move or tear down the steel grating after installation, we should install the steel grating with fixing clips.

- The diameter of the spiral is more than 8 mm.

- The distance of the installation could be adjusted according to the tolerance. The smallest installation distance of the steel grating should be 3 mm and the smallest installation distance between the steel grating and the structure should be 10 mm.

The installation method.

The welding.

- We should weld the steel grating on the frame and it could form the permanent connecting.

- We should clean the galvanized coating, paint, rust, oil and water on the steel grating and the frame.

- The welding line length should be more than 25 mm and the height of the welding angle should be more than 5 mm.

- We should remove the slag and splash after welding and paint the zinc rich on the steel grating surface.

Install the fixing clips.

The steel grating structure is light. It owns good carrying capacity. The steel grating is safe and non slip. It is easy to install and tear down. It does not need much material and it is durable. The steel grating owns aesthetics. The steel grating is ventilated and transparent. It's also easy to clean the steel grating. These steel bar gratings is widely used in the projects such as petro-chemical industry, firepower electric generation, water power industry, harbor and docks, pharmacy, auto manufacture, paper making, city planning and real estate. The steel grating can be used as platform, floor, corridor channel, stair tread, trestle, wall fence, trench cover, well cover, ceiling board and other facilities. We would use the steel grating for cement plant. We use the steel grating as the platform, corridor channel and stair tread.

The steel grating with serrated type is more strong and anti-slipping.

The structure.

The steel grating could be used as the overhaul platform, such as humidity tower, dust collector, hoist and feeder equipment. It is also used for support corridor, belt conveyors, screw conveyors, chain conveyors, air transport chutes corridor and platform. Steel grating is used for cable bridge corridor, the connection among the building channel, the equipment inspection channel and stairs.

The design demands.

The loads.

The loads for the steel grating should meet the design needs of the safe loads needs. For the single walkway channel, the loads should be more than 3.0 KN /m2. For the double walkway channel , the loads for the steel grating should be more than 5.0 KN /m2. For the high density walkway board, the loads should be more than 7.5 KN /m2. For the steel grating on the traffic road, the loads would increase 25% when the wheel pressure increase 10%. If there are cutouts on the steel grating, the other parts should have the same loads.

The design demands for the platform passage.

- The deformation degree should not be more than the 1 /200 of the span when the steel grating platform are under loads. The deformation degree could not be more than 10 mm.

- The steel grating would not deform when the real loads is 1.5 times that of the design loads.

- The steel grating would not crack when the real loads is 3.0 times that of the design loads.

The design demands for the stairs tread.

- The deformation degree for the tread should not be more than the 1/200 of the span under the design loads. And the biggest deformation degree could not be more than 6 mm.

- The stairs tread would not deform when the real loads is 1.5 times that of the design loads.

- The stairs tread would not crack when the real loads is 3.0 times that of the design loads.

The steel grating design.

The spacing between the bearing bar steel is 30 mm, 35 mm or 40 mm. We should decrease the process times and the wastage, and design the steel grating as the following demands.

- The size of the steel grating is 6000 mm × 1000 mm. The distance among the boards should be 1000 mm. The gap between the boards should be 3–10 mm. We should use the last board to make the size complete.

- If the width of the board is less than 1000 mm, we should choose a close width of the steel grating from the manufacturer.

- The length of the steel grating can be optional, but it is best to be an integral multiple of 50 mm.

- The width of the stairs tread should be 700 mm, 800 mm or 900 mm.

The installation.

The installation demands.

- We should install the steel grating according to the steel structure. The steel grating would not move horizontally and would not be out of the support frame.

- The support length on the edge of the steel grating should be more than 25 mm.

- If we do not need move the steel grating, we should install the steel grating by welding and weld the steel grating on the frame.

- If we need move or tear down the steel grating after installation, we should install the steel grating with fixing clips.

- The diameter of the spiral is more than 8 mm.

- The distance of the installation could be adjusted according to the tolerance. The smallest installation distance of the steel grating should be 3 mm and the smallest installation distance between the steel grating and the structure should be 10 mm.

The installation method.

The welding.

- We should weld the steel grating on the frame and it could form the permanent connecting.

- We should clean the galvanized coating, paint, rust, oil and water on the steel grating and the frame.

- The welding line length should be more than 25 mm and the height of the welding angle should be more than 5 mm.

- We should remove the slag and splash after welding and paint the zinc rich on the steel grating surface.

The fix clips are the parts which helps to install the steel grating.

Install the fixing clips.

Table 1: The fix clips number

| The steel grating size |

0.5–1.5 m |

1.5–3.0 m |

3.0–4.0 m |

4.0–5.0 m |

5.0–6.0 m |

| The fix clips number |

4 |

6 |

8 |

10 |

12 |

- We should install the fix clips on the frame. There should be 4 sets of fix clips every 1 m2 and we should install the fix clips on the four angles.

- If the steel grating is long and there is support frame in the middle we could install the fix clips according to the table one.

- The fix clips consist of the upper clip, lower clip, bolt, nut and washer.

- We should assemble the fix clips like the picture. The lower clip goes through the steel grating and the upper clip is installed on the bearing bar. The lower clip is putted on the support frame. We use the nut to fix a position for the lower clip groove. We should tighten the bolt and the clips should be close to the frame. The tightening torque is 17–20 N·m.

- When the steel grating is installed on the support frame we should tighten them. We should make sure the steel grating would not move and cause safe problem.

- After the installation, we should maintain for the steel grating. We should tighten the fix clips in time when the fix clips is loose.

Install the stairs tread.

- The steel stairs tolerance should be of the design requirements.

- The height of the stairs tread and its horizontal distance should be positioned according to the demands.

- We should clean the galvanized coating, paint, rust, oil and water on the stairs tread and the stepping board surface.

- If there is big gap between the stepping board and the stairs, we should fill it with the thin steel board and weld it. The height of the welding part should be more than 5 mm around the bearing bar.

- The connecting for the handrail railing.

- We weld the cross bar joint with intermittent welding method and clean the welding slag and rough welding tumor. We should paint the zinc rich on the railing.

- We should move the column to the installation position and place the bar abutment on the middle of the ball. Then we should fix the column.

- If necessary, we should weld out of the ball and clean the welding slag, remove the welding tumor. Finally we should paint the zinc rich on it.

- If there is zinc residue left on the column hole, we should insert a short pipe into the hole and rotate for two or three times. We could also file with a file and we should paint zinc rich when the zinc layer falls off.

- We should adjust the height for the column and install the cross bar into the column.

Figure 3: Serrated surface pressed steel grating.

Figure 4: Pressed steel grating can be used as floors in the plants.

Table 1: The fix clips number

| The steel grating size |

0.5–1.5 m |

1.5–3.0 m |

3.0–4.0 m |

4.0–5.0 m |

5.0–6.0 m |

| The fix clips number |

4 |

6 |

8 |

10 |

12 |

- We should install the fix clips on the frame. There should be 4 sets of fix clips every 1 m2 and we should install the fix clips on the four angles.

- If the steel grating is long and there is support frame in the middle we could install the fix clips according to the table one.

- The fix clips consist of the upper clip, lower clip, bolt, nut and washer.

- We should assemble the fix clips like the picture. The lower clip goes through the steel grating and the upper clip is installed on the bearing bar. The lower clip is putted on the support frame. We use the nut to fix a position for the lower clip groove. We should tighten the bolt and the clips should be close to the frame. The tightening torque is 17–20 N·m.

- When the steel grating is installed on the support frame we should tighten them. We should make sure the steel grating would not move and cause safe problem.

- After the installation, we should maintain for the steel grating. We should tighten the fix clips in time when the fix clips is loose.

Install the stairs tread.

- The steel stairs tolerance should be of the design requirements.

- The height of the stairs tread and its horizontal distance should be positioned according to the demands.

- We should clean the galvanized coating, paint, rust, oil and water on the stairs tread and the stepping board surface.

- If there is big gap between the stepping board and the stairs, we should fill it with the thin steel board and weld it. The height of the welding part should be more than 5 mm around the bearing bar.

- The connecting for the handrail railing.

- We weld the cross bar joint with intermittent welding method and clean the welding slag and rough welding tumor. We should paint the zinc rich on the railing.

- We should move the column to the installation position and place the bar abutment on the middle of the ball. Then we should fix the column.

- If necessary, we should weld out of the ball and clean the welding slag, remove the welding tumor. Finally we should paint the zinc rich on it.

- If there is zinc residue left on the column hole, we should insert a short pipe into the hole and rotate for two or three times. We could also file with a file and we should paint zinc rich when the zinc layer falls off.

- We should adjust the height for the column and install the cross bar into the column.

Figure 3: Serrated surface pressed steel grating.

Figure 4: Pressed steel grating can be used as floors in the plants.