Professional Steel Grating & Safety Grating Manufacturer

- Home

- Steel Grating

EnZar® Steel Grating

- Galvanized Steel Grating

- Painted Steel Bar Grating

- Stainless Steel Grating

- Aluminum Grating

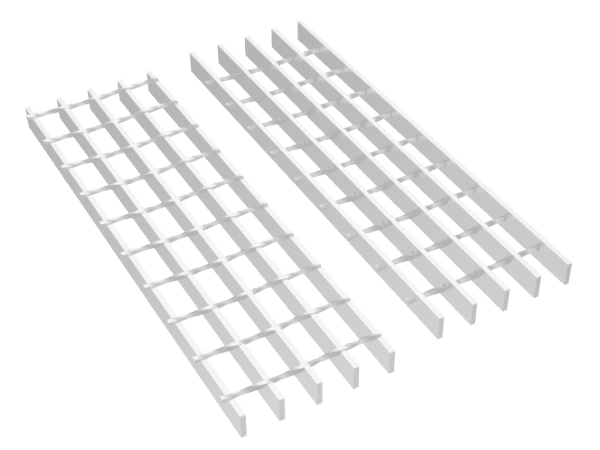

- Welded Steel Grating

- Press-locked Steel Grating

- Swage-Locked Grating

- Riveted Grating

- I Bar Steel Gratings

- Louver Steel Grating

- Standard Steel Grating

- Heavy Duty Steel Grating

- Dense Steel Grating

- Irregular Steel Grating

- Compound Steel Grating

- Steel Grating Accessories

- Serrated Welded Steel Grating

- Serrated Press-Locked Steel Grating

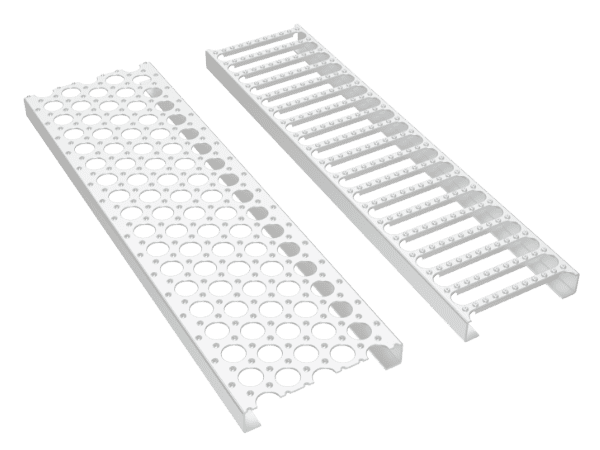

- Plug Grating

- Grating Stanchion Railing Ball Joint Handrail

- Modular Handrails Kits and Self-Closing Safety Gate

- Safety Grating

- Application

EnZar® Application

- Solar Power HDG Grating Walkway

- Stainless Steel Wedge Wire Floor Grate

- Aluminum Gutter Guard

- Swaged Louvers

- Platform Grating

- Walkway Grating

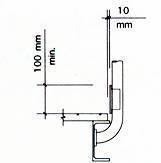

- Stair Tread Steel Grating

- Trench Cover Grating

- Trench Grates & Frames

- Grating Fence

- Handrail Infill Grating

- Bridge Decking Grating

- Transformer Gratings

- Steel Grating Ceiling

- Steel grating Sun Shade Panels

- Steel Grating Floor

- Steel Grating Operating Platform

- Steel Grating Drilling Platform

- Steel Grating Tree Cover

- Steel Grating Balcony Fence

- More Application +

- Projects

EnZar® Projects

- Singapore Project Steel Grating Walkway and Stair Tread

- Grating Ball Joint Stanchions in Australia Workshop

- Stainless Steel Grating for Factory Walkway in Mexico

- Steel Grating for the Walkway of the Bridge in Kazakhstan

- Painted Steel Grating for China Indoor Walkways

- Aluminium Grating for Canadian Office

- Aluminum Perforated Metal Plates for Singapore University

- Aluminum Fence in Solomon University

- Service

- About Us

- Contact Us