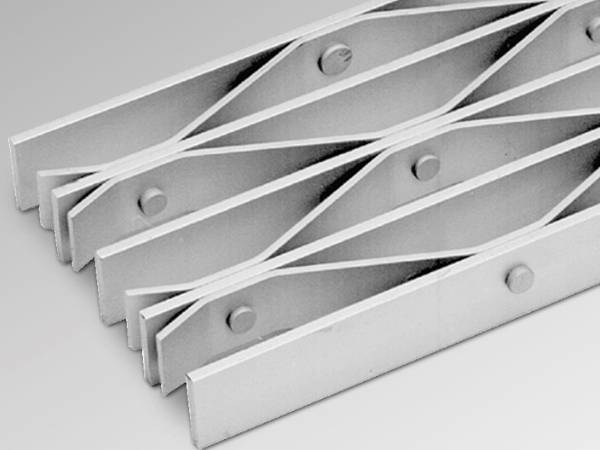

Riveted bar grating with serrated surface

Riveted bar grating derives its name from the use of high-strength rivets to bond the reticulated bars to the bearing bars. Mechanically and hydraulically operated riveting tools are used to individually cold press each rivet, which fuses the reticulated and bearing bars together and forms a solid joint. Riveted bar grating with smooth and serrated surfaces can be constructed of either carbon steel, aluminum or stainless steel.

Riveted bar grating with serrated surface

Riveted bar grating with smooth surface

When compared to other types of grating, such as welded or aluminum swage-locked, riveted bar grating has many advantages in industry applications.

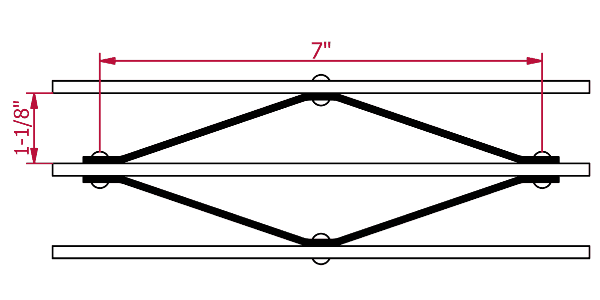

18-R-7

12-R-7

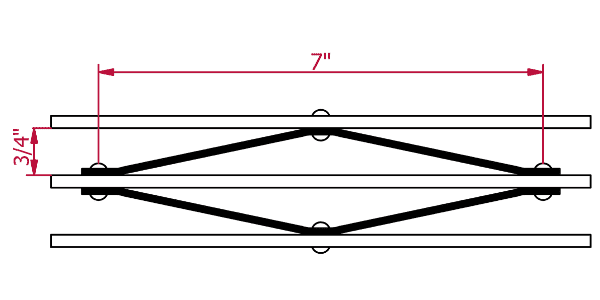

18-R-3.5

12-R-3.5

Riveted bar gratings are a strong, durable and impact resistant solution. Riveted grating offers superior resistance to impact and fatigue. In addition, riveted bar grating products are available with a smooth or serrated surface that is ideal for high traffic areas.

They are suitable for applications requiring high strength and stiffness, including high-traffic pedestrian areas such as building entrances, bridge walkways and sidewalk grates or transit corridors for light rolling loads such as handcarts, forklifts and pallet jacks. They are widely used in the following areas:

Riveted grating floors and stairs

Riveted grating walkway

Riveted grating bridge decking

Riveted grating walkway in pier

Riveted grating operating platform

Riveted grating well cover