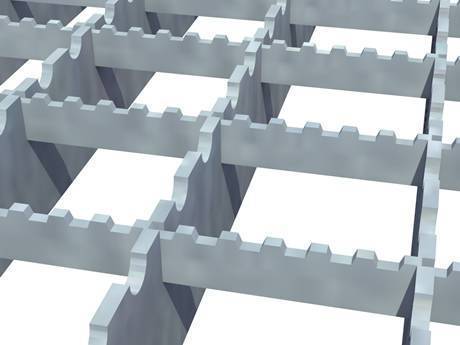

Figure 1: Pressed steel grating.

What is pressed steel grating

Pressed steel grating is a grating with mesh hole structure in which the cross bar is pressed into the bearing bar under high pressure. The materials of this product are low carbon steel, stainless steel and aluminum.

Figure 1: Pressed steel grating.

The finished product can be treated with hot zinc to improve the corrosion resistance and durability of the products. The galvanized pressed steel grating has a beautiful appearance.

Pressed steel gratings are mainly used for food, chemical and some other productions, and it also can be used in a variety of architectures. If necessary, it is also possible to increase the anti-slip performance by adding serrations on the bearing bar and cross bar.

Pressed steel grating is produced by pressing the cross bar to bearing bar which the load pressure of 500 tons with the method of cold pressing. For the gratings formed in this way, it is necessary to cut them into a well-sized cell. At present, Europe's largest factory is also using this technology, it can achieve high strength and record torsional strength.

In addition to the daily application, pressed steel grating also helps to solve the environmental and aesthetic problems of metropolitan architecture and landscaping. For example, pressed steel grating also can be used in the trees of streets, squares, parks, it can protect the roots of trees, increase the pedestrian area of park, it will not hinder the sun, air and water.

Figure 2: Pressed steel grating can be used to protect the trees.

In addition to high strength, durability, easy maintenance and installation, this product has additional advantages - environmental protection.

Key features of pressed steel grating

Advantages of press-locked steel grating

Figure 3: Serrated surface pressed steel grating.

Figure 4: Pressed steel grating can be used as floors in the plants.